order(moq):

1 PCSPayment:

T/T, L/C, D/P, Western Unionproduct origin:

ChinaColor:

Yellow Black or Customizedshipping port:

Xiamen,ChinaLead Time:

30 DaysFinish:

Smooth25MnB Steel Excavator Track Pads Undercarriage Spare Parts Track Shoe

1. Our Advantages

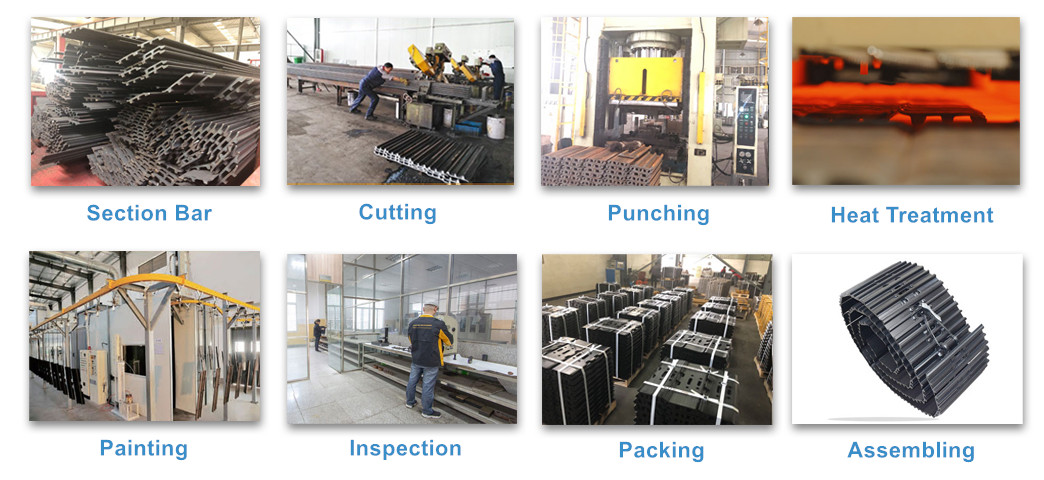

2. Track Shoe Production Processes

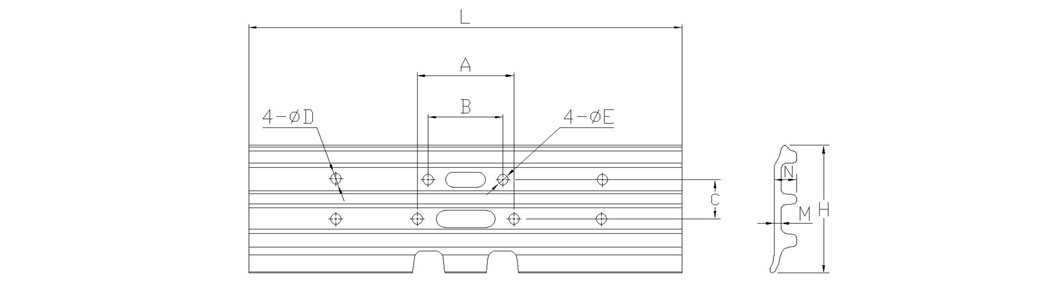

3. Main Dimensions of Installation

Main Parameters

| Suitable Model | Main Dimensions of Installation | ||||

| A | B | C | E | H | |

| PC300/EX300-5/EX350LC-5/ZAX300/SH330 | 178.4 | 140.4 | 76.2 | φ22.8 | 250 |

| EX400/EC460/PC300HD/PC400/EX400/PC360 | 184 | 146 | 76.2 | φ22.8 | 250 |

| PC400-5/6/PC300HD-3/5/PC360LC-1/3/5 | 184 | 146 | 76.2 | φ24.6 | 247 |

| E330/SK300/SK400 | 190 | 140 | 76.2 | φ23 | 250 |

| PC300-3/5/PC300-5/DH280/EX300-3/EX270 | 178.4 | 138.4 | 72.2 | φ20.5 | 236 |

| CAT325/E325ST | 179 | 129 | 72 | φ21.0 | 236 |

| DH220/EC210/R220/SK230/PC230/PC200-5/6 | 160.4 | 124.4 | 62 | φ20.5 | 219 |

| EX200-2/5/EX210/PC200-2/3/ZAX230/EX220 | 160.4 | 124.4 | 62 | φ18.5 | 219 |

| E200B/EL200B/E320C/SK200/SK230/SH200 | 155.57 | 119.57 | 69 | φ21.0 | 219 |

| EX100/ZX120/SX120/EX120/DH120/CAT312 | 108 | 108 | 60.4 | φ16.5 | 190 |

| PC100-5/6/PC120-5/6/PC130-6 | 102.4 | 86.4 | 57 | φ16.3 | 190 |

| EX200-1/R200 | 144.46 | 125.41 | 58.74 | φ16.3 | 190 |

| PC120-3 | 112.4 | 82.4 | 57 | φ14.5 | 165 |

| EC60-1/ECR88/EX60-2/3/EX75UR | 90 | 90 | 55 | φ14.5 | 165 |

| PC60-3/S50/D20/ZY65 | 99 | 72 | 43.4 | φ12.5 | 154 |

| CAT305/EX40/SY55-65 | 104 | 80 | 46 | φ12.5 | 154 |

| PC40-7/PC45/PC50-7/8/SK40 | 94 | 64 | 47 | φ12.2 | 154 |

The models above are just for reference, we can't list all models here. we can supply more products as your requirements. Please feel free to send us your inquiry.

4. Hot Sale Products

5. Why Choose Us?

6. Compatible Brands

7. Tips on Track Shoe Selection

The wide variety of working conditions makes choosing the right shoe become very important . A good rule is choose the narrowest shoe that provides adequate flotation. Shoes that are too wide will loosen, bend and crack more easily. They require more power to run. Shoes of the correct width give maximum performance and the lowest possible cost to the entire system.

We are a professional Excavator and Bulldozer spare parts manufacturer in China, we offer customized products that could meet your various needs. Follow us, we will exceed your expectation.

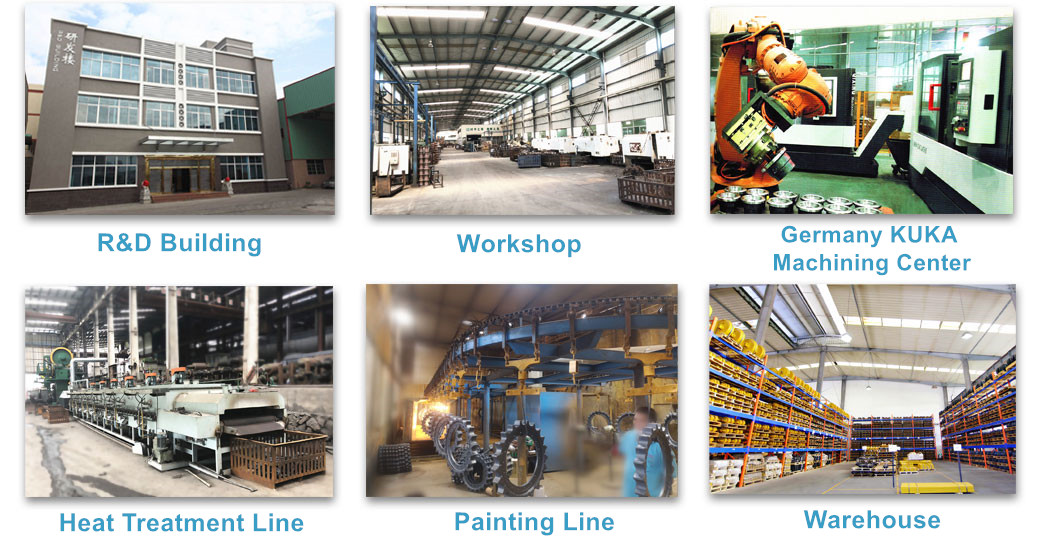

1. Our Factory View

2. Our Inspection Equipments

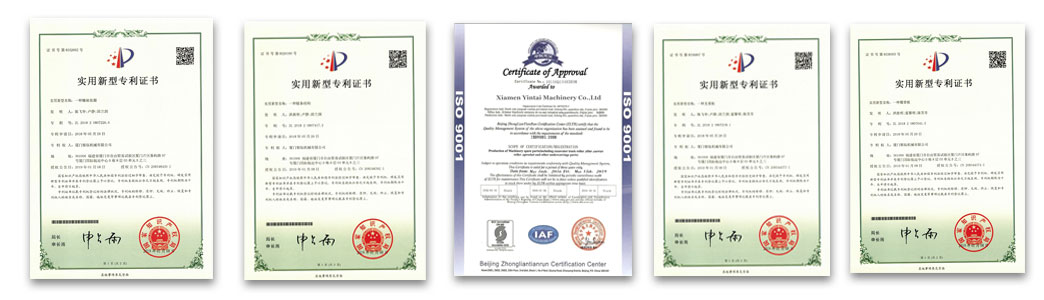

3. Our Main Certificates

4. Our Packing