Track roller is an essential component of the undercarriage system in a bulldozer, and it serves several important functions

order(moq):

1 PCSPayment:

T/T, L/C, D/P, Western Unionproduct origin:

ChinaColor:

Black Yellow or Customer Requiredshipping port:

XiaMen, ChinaLead Time:

30 daysPacking:

Wooden Pallet PackingCAT D11N/D10N Track Roller High Strength Bottom Roller

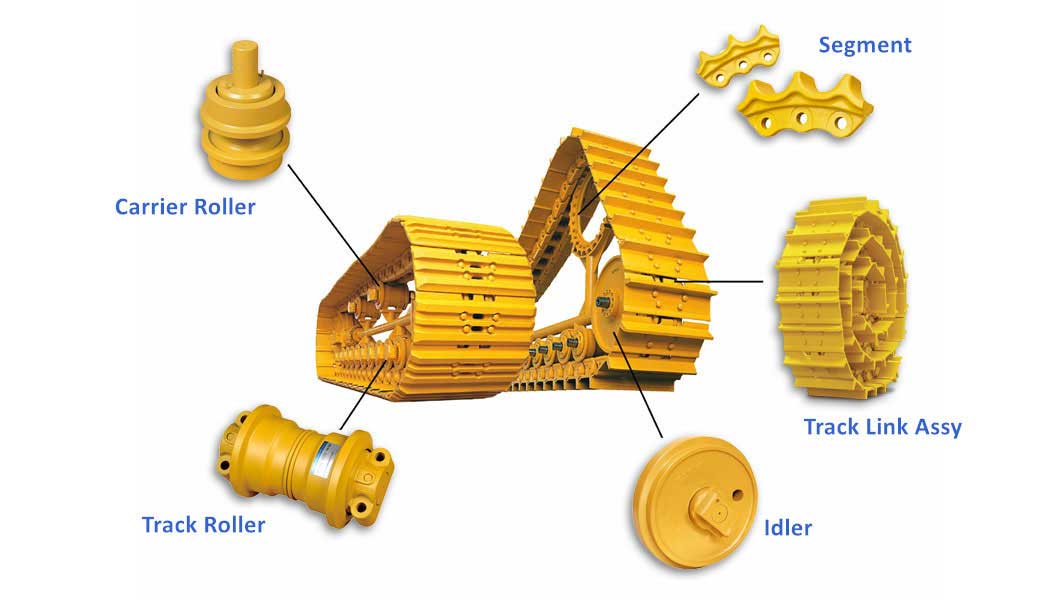

1. What's the Function of Track Roller?

The track roller is an essential component of the undercarriage system in a bulldozer, and it serves several important functions:

* Support and Load Distribution: The track roller supports the weight of the bulldozer and distributes the load evenly across the length of the track. It helps bear the weight of the bulldozer and the forces generated during operation, preventing excessive stress on other undercarriage components.

* Track Tension Adjustment: The track roller plays a crucial role in maintaining proper track tension. By adjusting the position of the track roller, the tension of the track can be controlled, ensuring optimal track performance, minimizing track slippage, and maximizing the life of the track components.

* Track Guidance: The track roller guides and guides the track along its path. It helps maintain the alignment and stability of the track, preventing lateral movement or derailment during operation.

* Load Absorption and Shock Damping: The track roller absorbs shocks and vibrations generated during the operation of the bulldozer. It dampens the impact forces and vibrations, providing a smoother ride, reducing fatigue on the machine, and enhancing operator comfort and control.

* Wear Resistance: The track roller is designed to withstand continuous contact with the track chain, which can exert significant wear. It is constructed using materials that offer high wear resistance, minimizing wear and extending the service life of the undercarriage.

* Track Chain Lubrication: Some track roller designs include lubrication mechanisms that facilitate the distribution of lubrication oil to the inner surfaces of the track chain. This reduces friction and wear, promoting smooth track movement and extending the life of the track chain and other related components.

2. Specification

Wheel Body

35MnB/50Mn/40MnB

Side Cover

QT500-7

Shaft

45# Steel

O-Ring

Rubber

Bimetal Sleeve

CuPb10Sn10

Hexagon Socket Bolt

JB/T 1000-1977

Lubricating Oil

40#

Model Number

D11N/D10N/D10L

Part Number

8P5604 8P5605

Colour

Yellow or Customized

Surface Hardness

HRC48-54

Technique

Forging / Casting

Packing

Fumigate Wooden Pallets

Certification

ISO9001

Warranty Time

2500h (Normal Life 4000h)

Delivery Time

30 days

3. Why Choose Us?

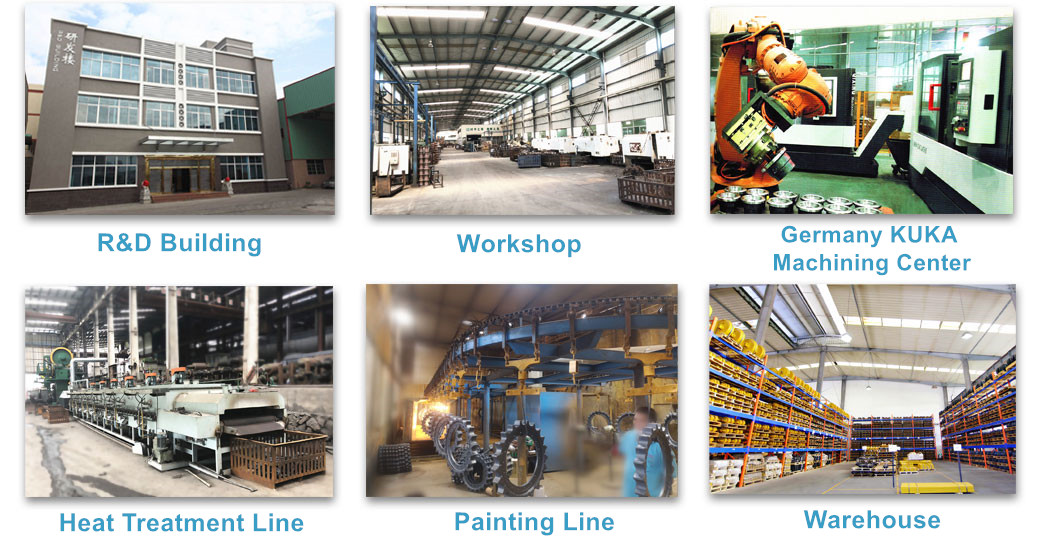

4. Manufacturing Processes

5. Hot Sales

6. Tips for Track Rollers

We are a professional Excavator and Bulldozer spare parts manufacturer in China, we offer customized products that could meet your various needs. Follow us, we will exceed your expectation.

1. Our Factory View

2. Our Inspection Equipments

3. Our Main Certificates

4. Our Packing