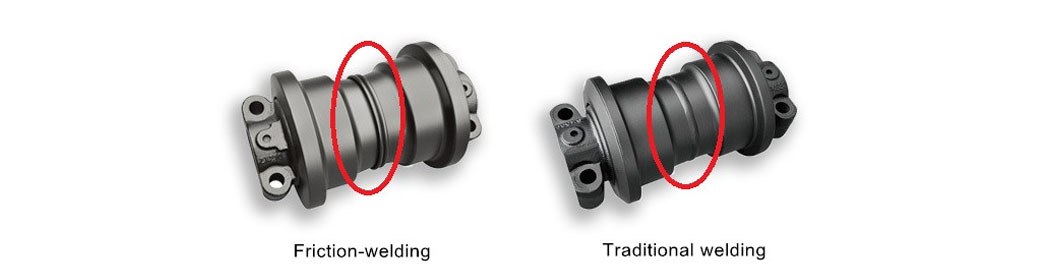

Friction welding track roller is better in the wear-resistance and has a longer working lifetime than traditional one. We are expert in this technology.

order(moq):

1 PCSPayment:

T/T, L/C, D/P, Western Unionproduct origin:

ChinaColor:

Black Yellow or Customer Requiredshipping port:

XiaMen, ChinaLead Time:

30 daysPacking:

Wooden Pallet PackingKomatsu PC200 Friction Welding Track Roller

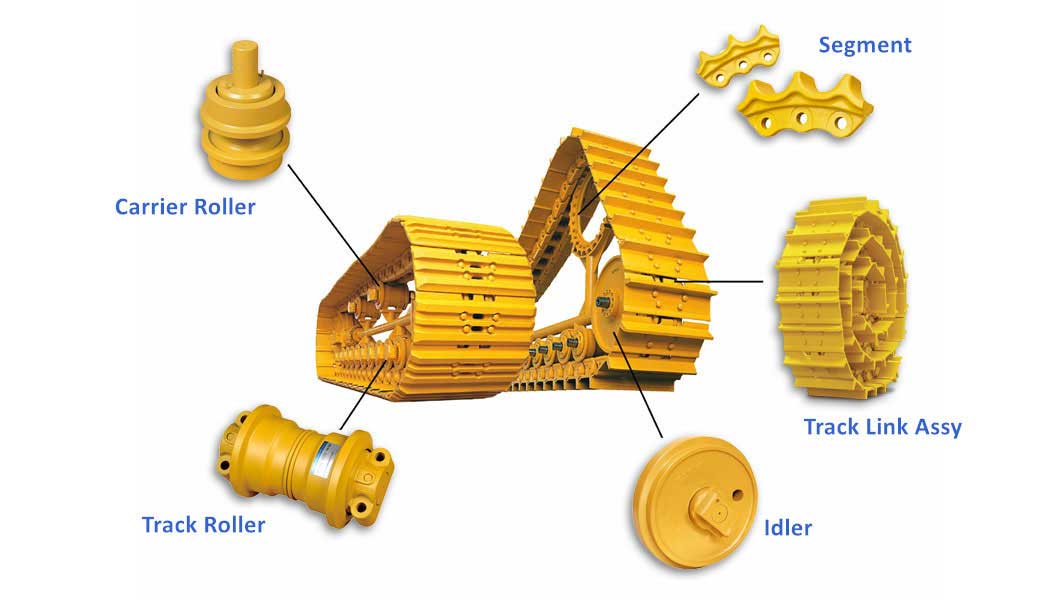

1. What is Friction Welding Roller?

The track roller has two kinds of welding methods, one is traditional and the other is friction-welding. Friction welding is a solid-state joining process, which could achieve reliable solder joints and create high-quality, high-strength joints with low distortion.

2. Differences between Friction-welding and Traditional Rollers

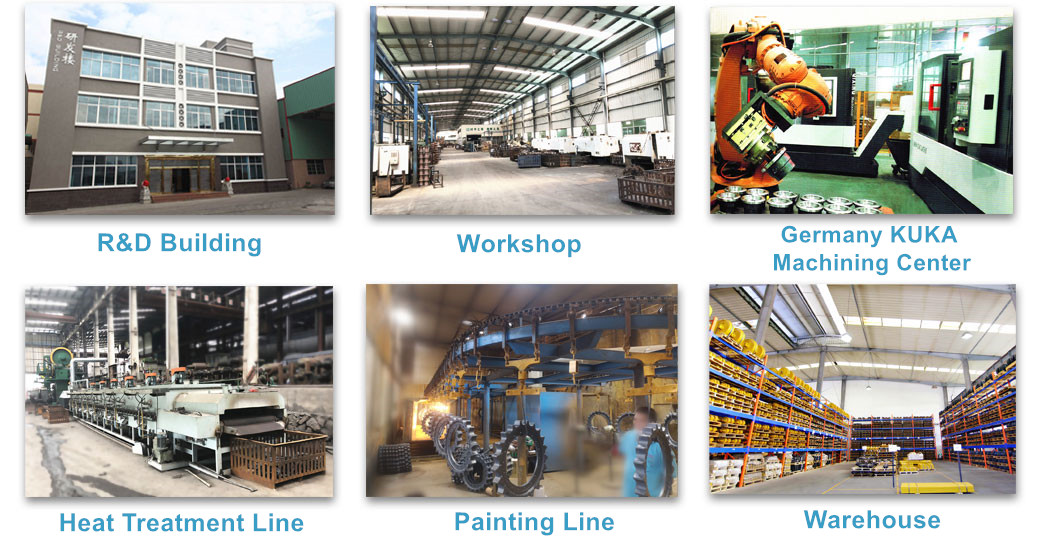

3. Why Choose Us?

4. Manufacturing Processes

5. Tips for Track Rollers

We are a professional Excavator and Bulldozer spare parts manufacturer in China, we offer customized products that could meet your various needs. Follow us, we will exceed your expectation.

1. Our Factory View

2. Our Inspection Equipments

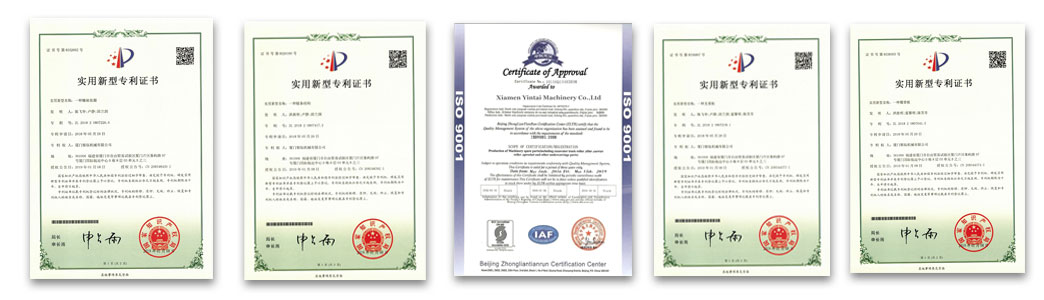

3. Our Main Certificates

4. Our Packing