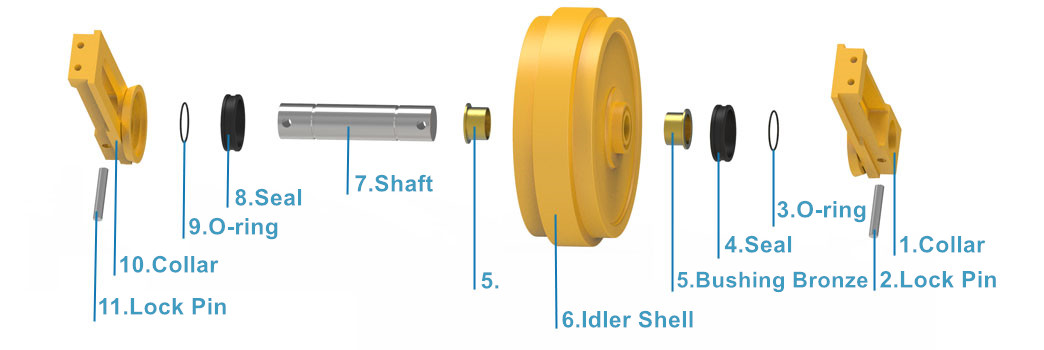

The idler is made of idler shell, shaft, brackets, bi-metallic bushing bronze and seal group.

order(moq):

1 PCSPayment:

T/T, L/C, D/P, Western Unionproduct origin:

ChinaColor:

Yellow Black or Customizedshipping port:

XiaMen, ChinaLead Time:

30 daysFinish:

SmoothEX300 Front Idler Casting Idler Group Assembly

1. Idler Structure

The idler is made of idler shell, shaft, o-rings, bi-metallic bushing bronze and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc.

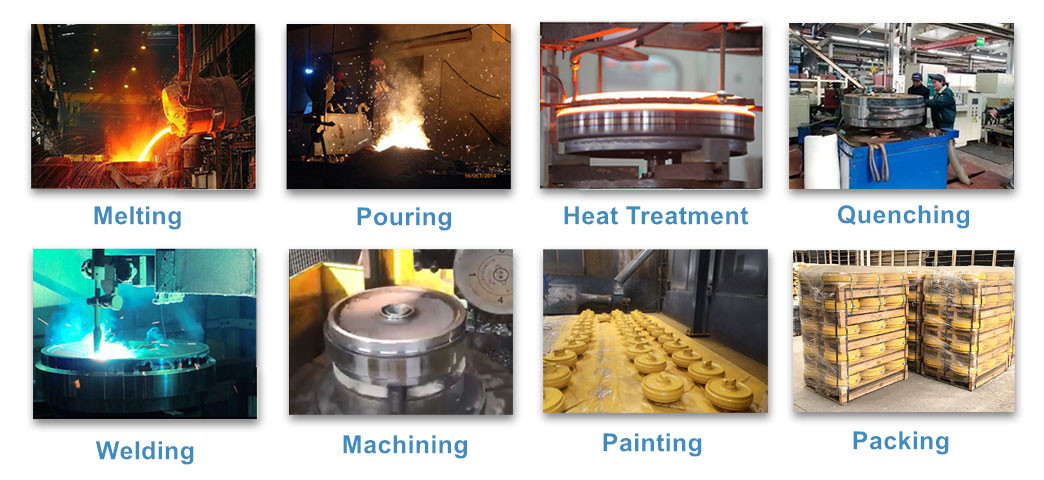

2. Idler Production Processes

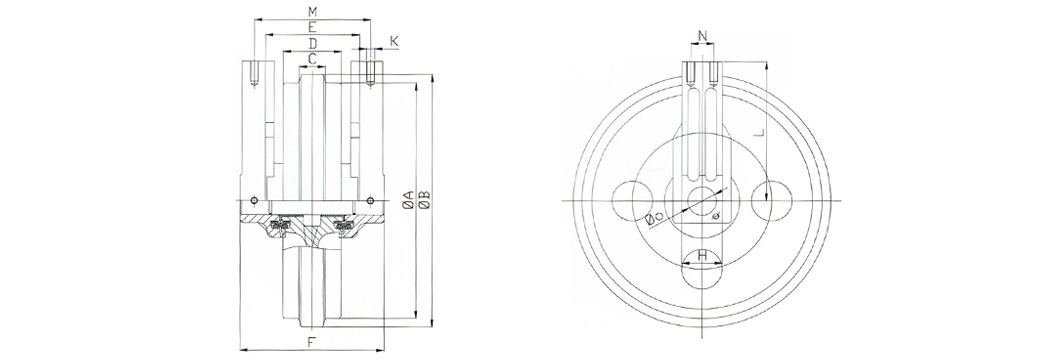

3. Main Dimensions of Installation

Main Parameters

| Brand | Model | Main Dimensions of Installation | ||||||

| A | B | D | L | M | N | O | ||

| HITACHI | EX40-3 | 358 | 318 | 92 | 240 | 140 | 60 | 40 |

| EX150-1 | 544 | 510 | 140 | 80 | 260 | 70 | 75 | |

| EX200-2 | 545 | 500 | 160 | 85 | 285 | 64 | 65 | |

| EX200-5 | 537 | 500 | 160 | 80 | 287 | 64 | 65 | |

| EX220-1 | 545 | 500 | 160 | 80 | 285 | 64 | 65 | |

| EX270-1 | 575 | 530 | 204 | 130 | 324 | 70 | 85 | |

| EX300-1 | 575 | 530 | 204 | 130 | 324 | 70 | 85 | |

| EX300-5 | 617 | 570 | 204 | 130 | 324 | 70 | 85 | |

| EX400-1 | 675 | 625 | 205 | 108 | 333 | 85 | 110 | |

The models above are just for reference, we can't list all models here. We can supply more products as your requirements. Please feel free to send us your inquiry.

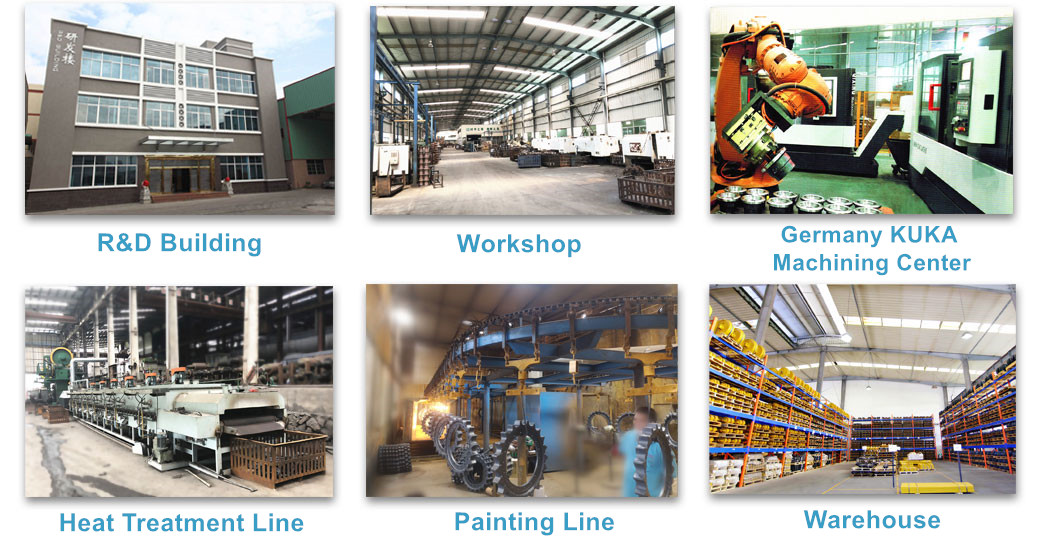

4. Why Choose Us?

5. Hot Sale Products

We are a professional Excavator and Bulldozer spare parts manufacturer in China, we offer customized products that could meet your various needs. Follow us, we will exceed your expectation.

1. Our Factory View

2. Our Inspection Equipments

3. Our Main Certificates

4. Our Packing